OXEA® Online Series

Online X-ray Elemental Analyzers since 2002 – multi patented technology

no nuclear measurement – no nuclear waste – no countermined material

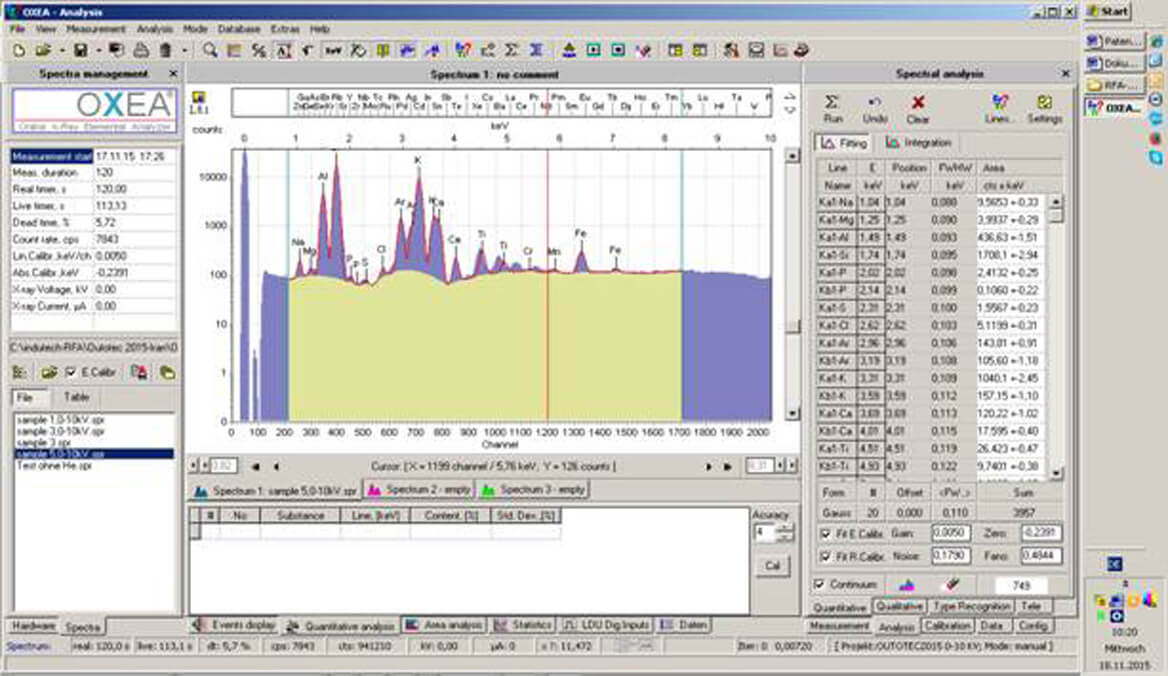

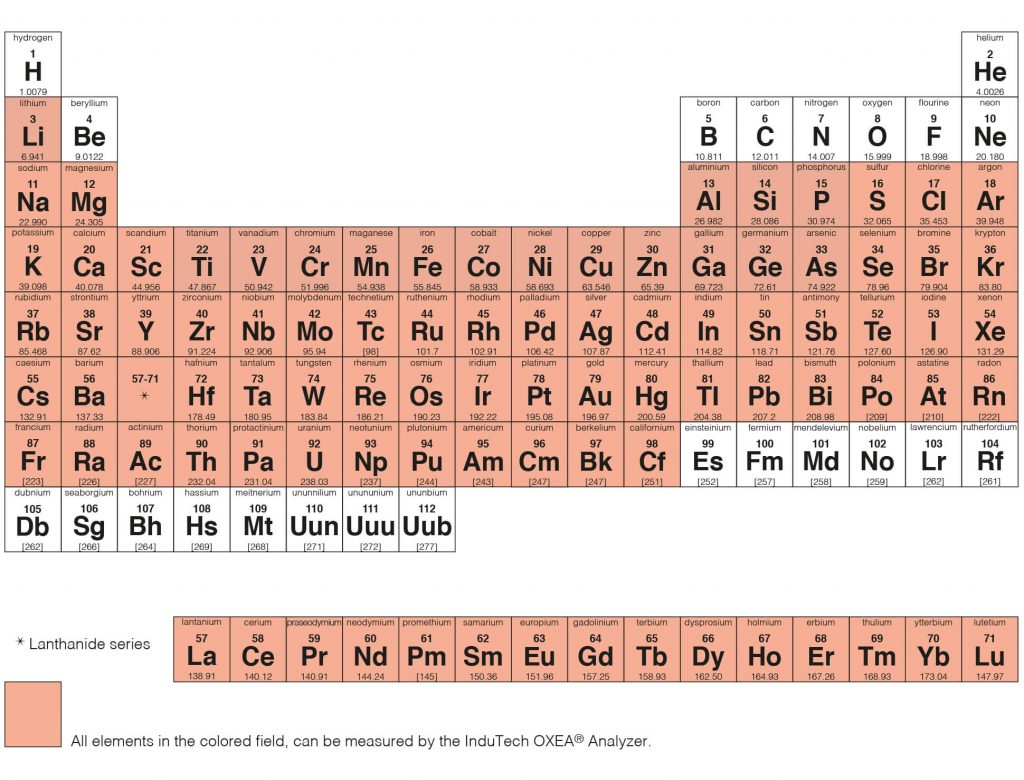

The OXEA® product line is based on X-ray fluorescence (XRF) and determines the elemental composition of the measured product. Indutech has modified the well known XRF technique, for online applications. All elements with an atomic number > 10 (Sodium and above) can be detected down to the ppm-range.

The OXEA® is applicable for all materials and can be used on the main conveyor belt and at any kind of bypass. The sensor box is easy to install in any applications.

The OXEA® was at first mainly used in power stations to determine the BTU, sulphur and ash content of coal and gives a high level of accuracy obtainable with online analyzers. In the meantime OXEA® is also used for a large variety of non-coal applications. OXEA® is protected by several worldwide patents.

This device is also available as explosion-proof versions for zone 21 or 22.

Remote Service

Remote service can be provided through internet connection for quick customer support, available for all devices. This saves time and money.

New Development special pneumatic lifting

To make maintenance easy and in an extreme short time, a pneumatic lift was developed with self adjustment of the OSB. This allows to lift the OSB pneumatically. In the service position the service door can be opened to get access to the X-ray tube and the detector system. Additionally the OSB can be manually turned by 90 degrees to check the bottom opening for the X-rays, and to clean it, if necessary. Furthermore the service position is a safe position, which can be selected in case of abnormal conditions, such as extremely overload on the belt.

The modularity of the OXEA® Systems:

allows a very easy adaption to the multifarious process conditions and requirements, e.g. at main belt, bypass belt, chute or other bypasses.

Analyzer Types

OXEA® 500-1

Measuring Principle:

XRF/backscatter over the belt ash analyzer

Measured Parameters:

Ash content

Advantages:

Contactless – Compensation of elemental ash composition

Limitation:

Particle < 75-100 mm (3“ – 4“) – Distance to surface 70 – 230 mm

OXEA® 500-3

Measuring Principle:

XRF/backscatter over the belt ash analyzer

Measured Parameters:

Ash content – Elemental composition of ash for elements with Z >19 (Potassium)

Advantages:

Contactless – Compensation of elemental ash composition

Limitation:

Particle < 75-100 mm (3“ – 4“) – Distance to surface 70 – 230 mm

OXEA® 600-1 / GTA 3000-1

Measuring Principle:

Dual Energy Gamma Transmition + OXEA® 500

Measured Parameters:

Ash content

Advantages:

Contactless – Compensation of elemental ash composition – Improved accuracy compared to OXEA® 500-1

Limitation:

Particle < 75-100 mm (3“ – 4“) – Distance to surface 70 – 230 mm

OXEA® 600-3 / GTA 3000-3

Measuring Principle:

Dual Energy Gamma Transmission + OXEA® 500

Measured Parameters:

Ash content – Elemental composition of ash for elements with Z >19 (Potassium)

Advantages:

Contactless – Compensation of elemental ash composition – Improved Accuracy compared to OXEA® 500-3

Limitation:

Particle < 75-100 mm (3“ – 4“) – Distance to surface 70 – 230 mm

OXEA® 1000

Measuring Principle:

XRF/backscatter

Measured Parameters:

Ash content – Elements with Z > 10

Advantages:

Compensation of elemental ash composition – Best accuracy

Limitation:

Particle size max. < 50 mm, avg. < 25 mm – Distance to surface ~8 mm – Sled or Bypass belt application

OXEA® 2000

Measuring Principle:

XRF/backscatter

Measured Parameters:

Ash – Sulphur – Elements with Z > 10

Advantages:

Compensation of elemental ash composition – Best accuracy

Limitation:

Particle size max. < 50 mm, avg. < 25 mm – Distance to surface ~8 mm – Sled or Bypass belt application

OXEA® 3000

Measuring Principle:

XRF/backscatter

Measured Parameters:

Ash – Sulphur – Volatiles – Ash fusion – Type recognition – Elements with Z > 10

Advantages:

Compensation of elemental ash composition – Best accuracy

Limitation:

Particle size max. < 50 mm, avg. < 25 mm – Distance to surface ~8 mm – Sled or Bypass belt application

FEATURES & BENEFITS

■ High precise, reliable online analyzers for real time in closed loop

■ Easy installation and calibration

■ Low maintenance cost

■ Easy or no licensing

■ Rapid return on investment

■ Environment friendly Analyzer

■ Meets all environmental requirements

■ Easy, safe, reliable, economical and secure

■ No radioactive source or nuclear waste

■ No radio activated material

New Developments / Improvements 2012

OXEA® Applications Include:

Coal Mines, Coking Plants and Power Stations

■ ash content

■ sulphur content

■ calorific value / inserts

■ ash fusion

■ indication for slagging and fouling

■ volatiles

■ trace elements, as arsenic

■ solid and ash content of slurries

■ complete elemental composition of ash

■ type recognition of coal

■ distinction between coal, coke, petrol coke and slag

■ moisture content

■ carbon in fly ash

■ slurry – down to Na

■ density, solid content, in pipes

Steel and Iron Industry

■ complete elemental composition of ore

■ basicity of sinter and ore

■ zinc content of converter dust up to 300°C

■ moisture content

Cement Industry

■ elemental composition of – raw meal | limestone | cement

■ moisture content

Potash Industry

■ potash content in silos

■ belt potash meter

■ potash belt weigher

■ all elements with an atomic number > 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content up to about 8 %

■ density, solid content, in pipes

Ore Mines and Mineral Processing Plants

■ elemental composition of ore and concentrates

■ copper

■ bauxite

■ magnesite

■ iron

■ platinum

■ gold

■ lead

■ further minerals

■ moisture content

■ slurry – down to Na

■ density, solid content in pipes

Recycling Industry

■ all elements with an atomic number < 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content

Chemical Industry

■ all elements with an atomic number < 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content

Pharmaceutical Industry

■ all elements with an atomic number < 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content

Wood and Paper Industry

■ all elements with an atomic number < 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content

Food Industry

■ all elements with an atomic number < 10 (sodium and above) can be detected down to the ppm range

■ type recognition to distinguish between different materials

■ other applications on request

■ moisture content

EU Research Project “DRAGON” (FP7) – 30 8389 in 2012

New improvement OXEA® within the EU Research Project “DRAGON” (FP7) – 30 8389 in 2012, It’s aimed to increase resource efficiency, and to reducing environmental impacts by sending less material to landfill. It is of great economic and environmental interest. The non nuclear, multi patented Technology of the InduTech OXEA® Online X-ray Elemental Analyzer is a precondition for an installation at a TBM. Within this Project we improved the accuracy and extended the detection limit for the low elements down to Na.

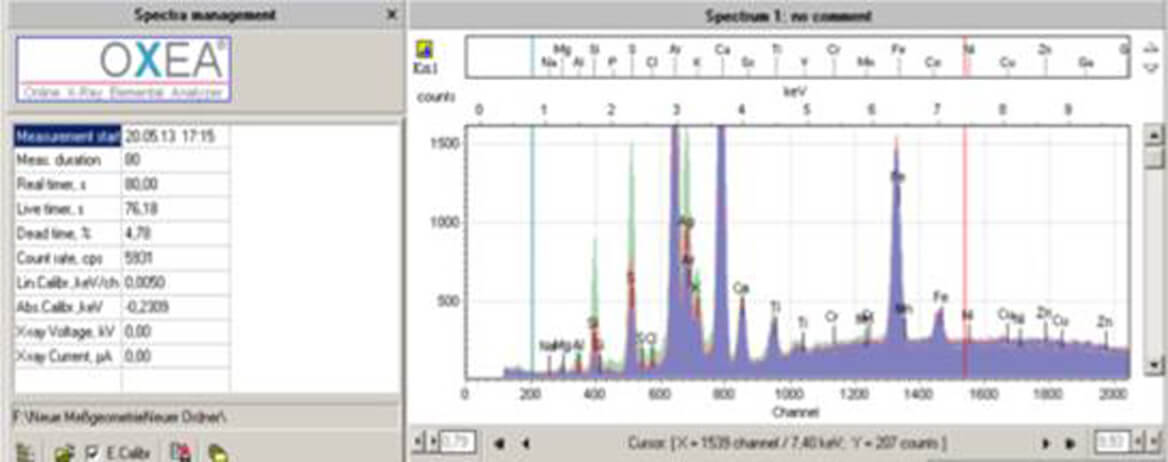

Improved OXEA® spectra quality 2012

Sodium Peak at the left edge of the OXEA® Spectrum 2012

® Online XRF Analyzer Series" data-bg="p:center top;f:contain;" class="rev-slidebg" data-no-retina>

® Online XRF Analyzer Series" data-bg="p:center top;f:contain;" class="rev-slidebg" data-no-retina>